If it seems as if the price of everything has gone up over the years, just look at speakers. Back when we started in 1970, a good bookshelf speaker sold for about $200 (although we sold equivalent speakers factory-direct for less than that). Recently, I’ve seen complete 5.1 systems in the newspaper for $199 including a subwoofer! In the same ad, I also saw large floorstanding speakers for under $150 each. Both of these were from well known brands that not too long ago were revered by those who knew fine audio.

With everything else going up in price over the years, how can a manufacturer make a low cost speaker? Let’s break it down in to 2 main approaches:

First is the approach that is used by virtually all of the major brands. These brands are found in stores, both brick and mortar locations and online. Here, the dealer will make typically 40-45% profit. So, if you buy a $200 speaker, the dealer will typically pay $110-$120 for it. Often, manufacturers go through distributors, which can get another 10%. The manufacturer typically winds up with $90-$100. They need to make a profit, so their cost could be half that. How do they build a speaker for that kind of money?

Over the years most of these once prestigious brands have been acquired by giant corporations with one goal; to use these names to generate the highest possible sales volumes. To sell more products, they have to be made to sell cheaply. Here are some of the ways they do it:

Vinyl Finish cabinets

– A simulated wood finish printed on a plastic sheet and glued to the wooden cabinet provides huge savings over a real wood finish or a high gloss hand finish. And this may be fine for some people, kind of like vinyl furniture compared with real leather.

Thin wooden cabinets without internal bracing

– A speaker cabinet is supposed to be solid. Vibrations can degrade the sound. Just knock on the side of a cheap speaker and you’ll know what we mean.

Plastic front baffle boards

– The baffle board is the front of the cabinet where the woofers and tweeters are mounted. Lately, manufacturers have been making a 1 piece baffle board that contains the basket structures of the woofers and tweeters. This means that instead of having to use separate woofers and tweeters with their associated metal baskets, they can build those speakers right into the plastic board. Also, they can mold shiny metal trim rings around the woofers and tweeters to make them look more impressive. This saves a lot of money. The downside of this is that if you blow a woofer or tweeter (which is more likely in a cheap speaker), you have to replace the entire baffle board with all the speakers, which is often as costly as the speaker itself.

Cheap Crossovers

– The crossover is the brains of the speaker. Its job is to channel the correct frequencies to the woofer and the tweeter with adding any distortion. Since the crossover cannot be seen from the outside of the speaker, this is an area that’s ripe for cost-cutting. There’s no getting around it, quality crossover parts are expensive. Cheap crossovers can add distortion, especially when you turn up the volume. Also cheap crossovers will degrade over time.

There are many other areas that manufacturers use to produce a cheaper speaker, but I think you get the idea. As you can see, theme here is compromise, compromise, compromise.

However, there is another way. And that is to build a high quality speaker without compromises. A way to get the price down is to sell the speakers factory direct. Then, you can take the profit that would normally go to the dealer and distributor and put in back into the quality of the speakers.

In the case of RSL, we had a choice. We could make an inexpensive speaker and make it even more inexpensive by selling it factory-direct. Or, we can build a speaker that qualifies as a high end reference quality monitor and make it affordable by selling factory-direct. We chose the later. We like to say, “built like a Ferrari, priced like a Kia.”

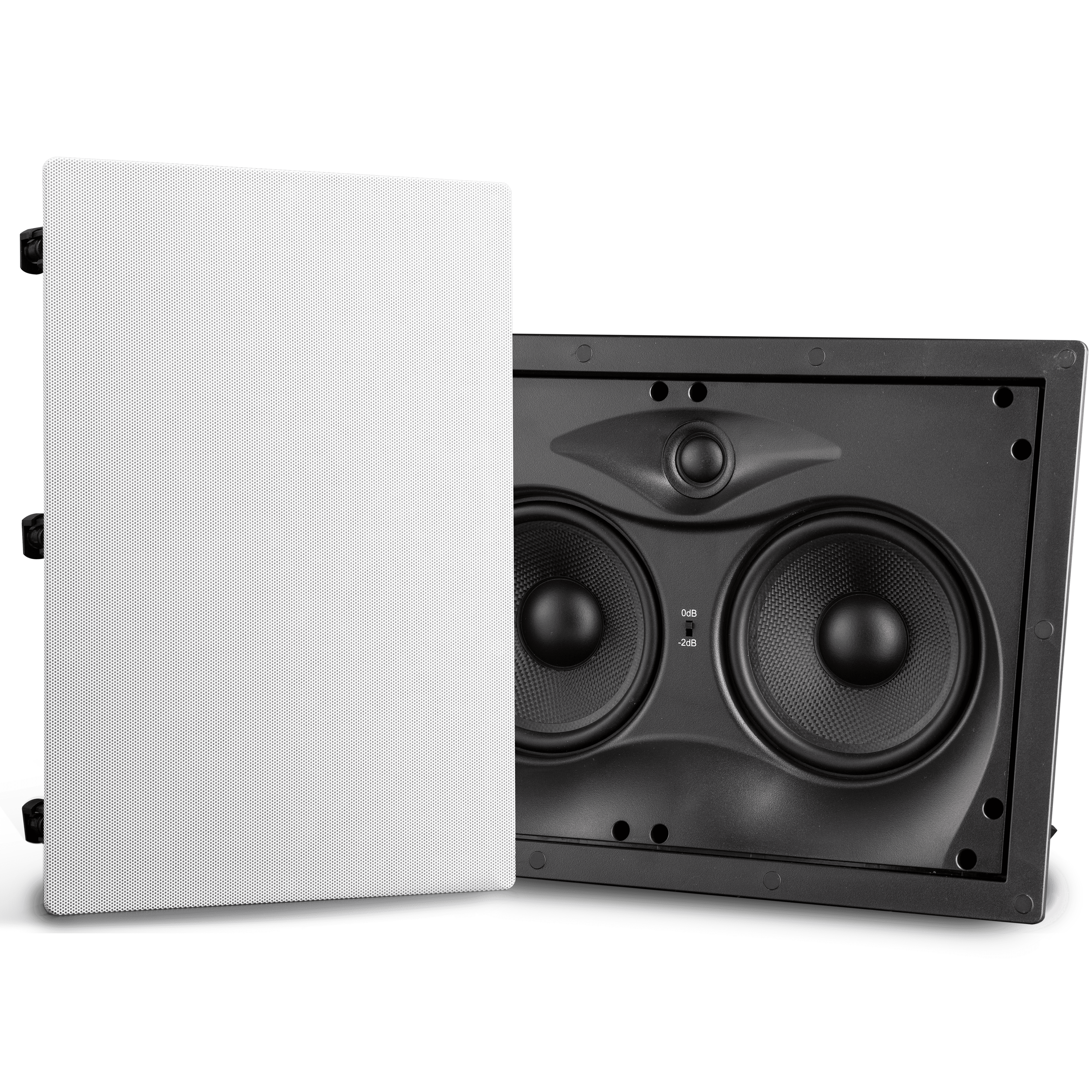

So with RSL speakers, you’ll find lavishly expensive hand-finished high gloss cabinets that are solid and internally braced, woofers with cast metal frames, highest quality crossover parts, metal grills held in place by invisible rare earth magnets, gold plated binding posts, etc. etc. There is absolutely no brand available through dealers that can offer this level of quality at our factory-direct prices.

Besides the construction quality, our patented Compression Guide Technology makes our speakers sound clearer and cleaner than other competing conventional loudspeakers.

We feel the extra quality is worth it. We get emails all the time from happy RSL customers who purchased their speakers in the 1970s are still enjoying them. The extra cost of a quality speaker over the long term is negligible.

Leave A Comment